Product Introduction

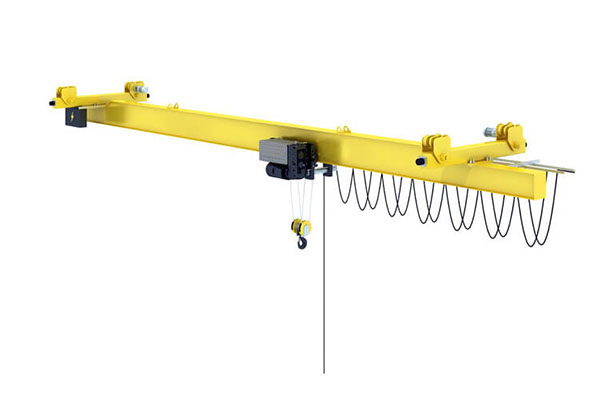

Main Parts: main girder, end carriages, lifting winch trolley, electric control box, overload limiter, limit switch, anti-collision buffer, insulation board, insulating motor, high temperature resistance power cables and electric components, cabin control with air-conditioner.

Ladle overhead crane is designed for transporting, pouring and charging hot metal in the process of smelting liquid metal, etc. It is also named casting overhead crane or metallurgy overhead crane, this type crane required to be able working with good condition in high temperature more than 60℃, and its insulation class is very high H grade.

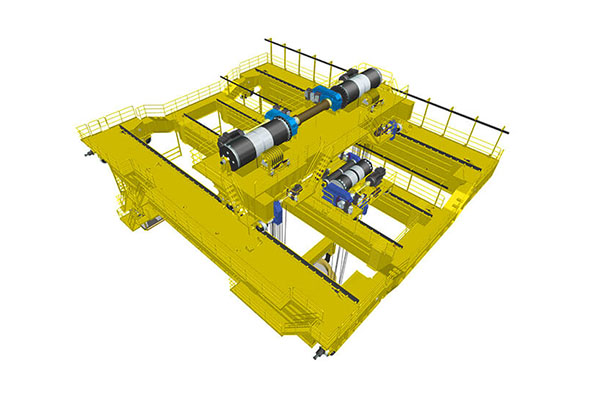

According to the crane structure, the ladle overhead cranes can be classified into Double Girder Double Rail Ladle Cranes, Four Girder Four Rail Ladle Cranes, and Four Girder Six Rails Ladle Cranes. The front two types are used for lifting middle and large scale ladles, and the latter one is used for extremely large scale ladles. KOSTA is capable of offering customized ladle overhead crane without lifting capacity limitation.

Product Advantages

- Double sets of independent action brakes is installed to the lifting mechanism..

- Heavy hammer and rotary lifting position limiters is installed and down position limiter will be installed when crane hoisting height is more than 20 m.

- Fault protection devices, such as, positive and negative contactor is installed to prevent dangerous in case of electricity power off.

- Insulating layer is installed at the bottom of main girders to prevent molten steel thermal radiation to ensure the long serving life of main girders.

- Special designed metallurgy motor is used, with insulation class H level, and motor protection grade IP54.

- Steel core wire rope is used, which is suitable for high temperature environment with the safety factor≧ 7.1; High temperature resistant cable is used for the power supply of trolley.

Safety Protection

We have the short circuit protection, emergency switch, interlock protection, overload protection, loss of voltage protection, grounding protection and voice-activated alarm lights and other safety protection devices

Technical Data

| Capacity | t | 5 | 10 | 20 | 32 | 50 | 75 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 13~31 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 | 6~18 | 6~18 |

| Lifting speed | m/min | 12.5 | 13 | 9.9 | 9.7 | 7.6 | 6.5 |

| Work duty | A7 | A7 | A7 | A7 | A7 | A7 | |

| Track type | P43 | P43 | P43 | QU70 | QU80 | QU100 |

FAQ

- Q1:What object to lift ? applications and working environment ?

- Q2:Lifting capacity:__ton?

- Q3:Lifting height (H):__ m ?

- Q4:Span (S):__m ?

- Q5:Travel bay distance:__m ? do you need us offer rails and runway beams ?

- Q6:Control mode: pendant control, remote control or cabin control ?

- Q7:Power source: AC 3Phase __V / __Hz ?