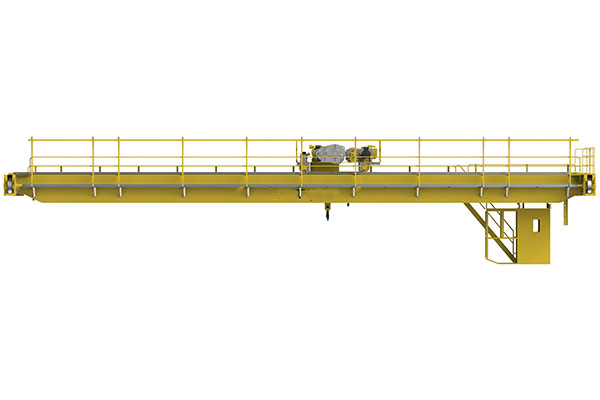

Product Introduction

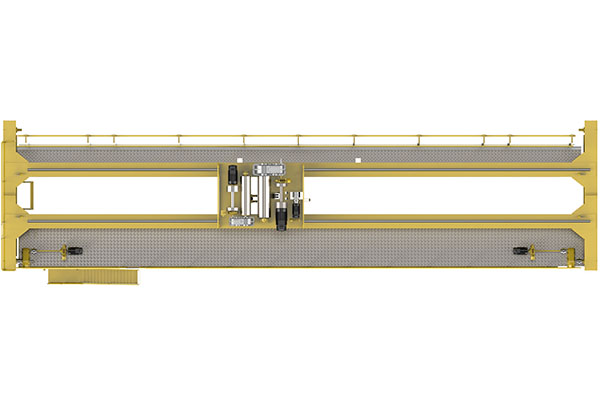

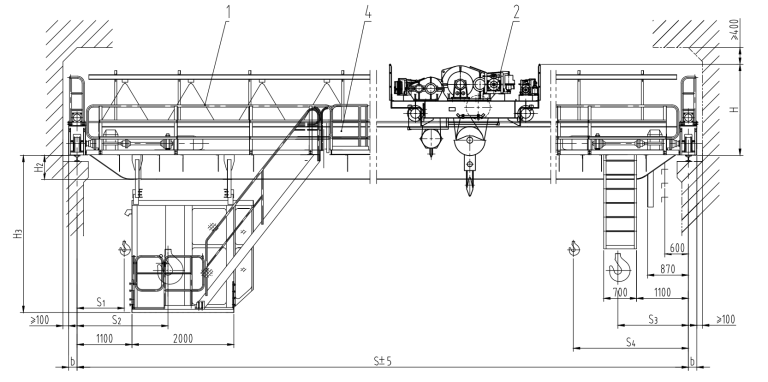

Main Parts: main girder, end carriages, lifting winch trolley, electric control box, cabin control, power cables, hook group, overload limiter, limit switch, anti-collision buffer.

QD model double girder bridge crane is a large and powerful heavy duty lifting equipment used for various fields and sectors, and suitable for industrial and mining enterprises, workshop or open space. Lifting equipment for loading, unloading and transporting materials in a fixed span, It is mainly applicable to the auxiliary lifting operations of mechanical processing and assembly workshops, metal structure workshops, machinery maintenance workshops, various warehouses, metallurgy and foundry workshops, etc.

Product Advantages

- Heavy duty with working class M6-M7, used in more complex and harsh working conditions.

- Good performance and high efficiency, more stable with heavy weight, long time working, easy maintenance

- Equipped with a variety of special slings for special operations, rain proof protection when used outside, lifting mechanism can provide two sets of safety devices as required to increase reliability.

- The vision of the cab room is wide, all the mechanisms are operated in the cab room, and the work is comfortable and flexible.

- Provide more effective lifting height as the hook can be pulled up between two girders.

- It is highly suitable for frequent and severe lifting occasions, with long service life more than 20 years.

Safety Protection

We have the short circuit protection, emergency switch, interlock protection, overload protection, loss of voltage protection, grounding protection and voice-activated alarm lights and other safety protection devices

Technical Data

| Lifting Capacity | t | 5 | 10 | 20 | 32 | 50 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | H(m) | 6~30 | 6~30 | 6~30 | 6~30 | 6~30 |

| Lifting speed | m/min | 12.5 | 8.5 | 7.2 | 6 | 6 |

| Work duty | A5~A6 | A5~A6 | A5~A6 | A5~A6 | A5~A6 | |

| Track type | P43 | P43 | P43 | QU70 | QU80 |

| Capacity | t | 75 | 100 | 160 | 200 | 320 |

| Span | S(m) | 10.5~31.5 | 13~31 | 13~31 | 13~31 | 13~31 |

| Lifting height | H(m) | 6~30 | 6~30 | 6~30 | 6~30 | 6~30 |

| Lifting speed | m/min | 3.9 | 3.1 | 3.7 | 2.6 | 2.4 |

| Work duty | A5~A6 | A5~A7 | A5~A7 | A5~A7 | A5~A7 | |

| Track type | QU100 | QU100 | QU120 | QU120 | QU120 |

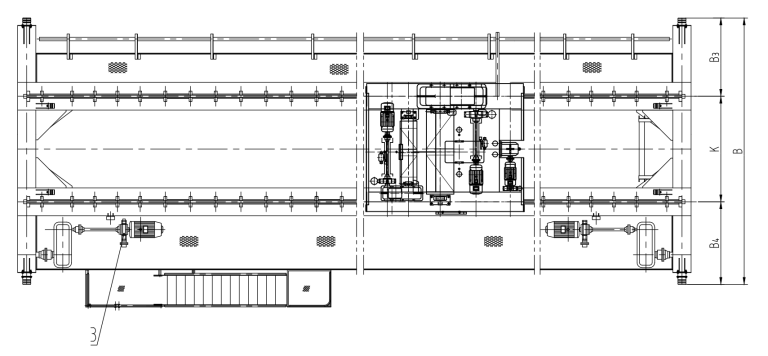

General Drawing

FAQ

- Q1:What object to lift ? applications and working environment ?

- Q2:Lifting capacity:__ton?

- Q3:Lifting height (H):__ m ?

- Q4:Span (S):__m ?

- Q5:Travel bay distance:__m ? do you need us offer rails and runway beams ?

- Q6:Control mode: pendant control, remote control or cabin control ?

- Q7:Power source: AC 3Phase __V / __Hz ?