Product Introduction

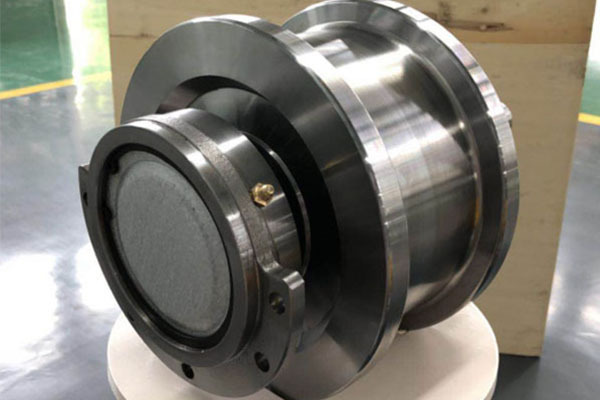

Crane wheels is used for crane end carriages traveling system of gantry crane or overhead cranes. Crane wheels are the most important parts in crane traveling system which are also the most vulnerable crane parts due to the friction between crane wheels and rail. Therefore, the crane wheels should be replaced when the flange wear, flange breakage and fatigue pitting happened.

Technical Description

- Double edge wheel is used for the bridge and gantry crane traveling,height of the flange is about 20mm-25mm.

- The wheel is made of the ZG340-640 cast steel or the ZG-50SiMn low alley steel, hardening depth of the wheel tread part will not lower than 20mm.

- Regarding the ZG340-640 cast steel wheel,hardness of the rolling surface is about 300-350HB,regarding ZG-50SiMn, hardness of the rolling surface is about 420-480HB.

- Single edge wheel is using for the trolley traveling of the bridge and gantry crane,height of the flange is about 25mm-30mm.

- The wheel is made of ZG340-640 cast steel or the ZG-50SiMn low alley steel, hardening depth of the wheel tread part will not lower than 20mm.

- egarding the ZG340-640 cast steel wheel,hardness of the rolling surface is about 300-350HB, regarding ZG-50SiMn, hardness of the rolling surface is about 420-480HB.

Product Advantages

- Wide range of crane wheels with the diameters of 150mm to 900mm (6”to 36”) are at your services.

- Various kinds of crane wheels are provided, such as, single and double flange wheel, forging and casting wheels, etc.

- Manufactured from high quality materials, which can be customized.Non-standard wheels can be designed and customized according to your various requirements.

- Supervised and advanced production ensures a uniform contour hardness in the tread and inner flange wear surfaces, while maintaining a ductile core to resist shock loads.

- High resistance to wear or flange fracture, pitting and spalling, with a long working life.

- Improve the life of your rail.Quick delivery within the required.

Technical Data

Wheel technical data for double girder overhead crane

| Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 |

| Wheel diameter | mm | 500 | 500/600 | 600/700 | 600/700 | 700/800 | 800 |

| Wheel material | ZG50SiMn , ZG340-640 or 40Cr forging | ||||||

| Matching track | P38 | P43 | P43 | P43 | QU70 | QU80 | |

Wheel technical data for single girder overhead crane

| Capacity | t | 3 | 5 | 10 | 16 | 20 |

| Wheel diameter | mm | 200 | 200 | 200/300 | 300/400 | 300/400 |

| Wheel material | Ductile iron, 40Cr forged or cast steel | |||||

| Matching track | P24 | P24 | P24/P30 | P38 | P38/P43 | |

Safety Protection

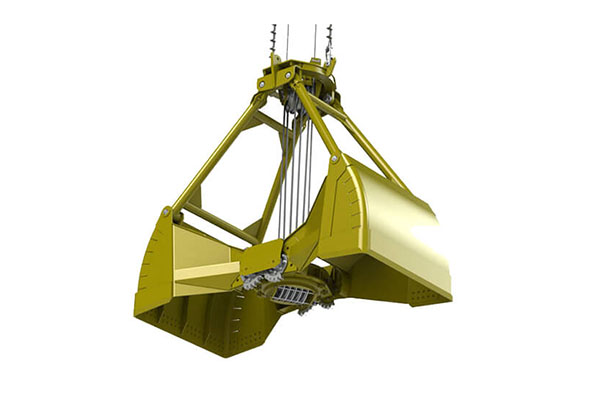

Lifting limit switch

Prevent the hook out of control when it has been lifted to the top position

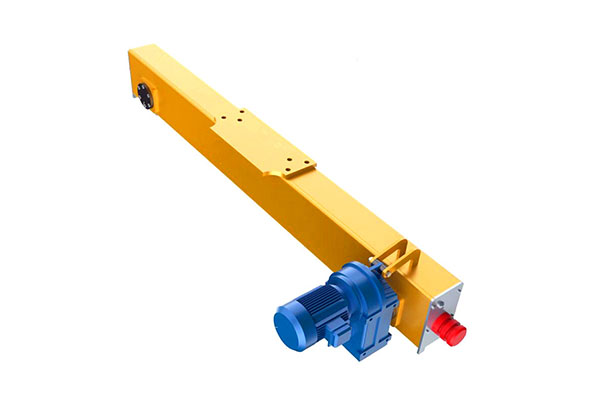

Traveling limit switch

Stop the crane traveling smoothly when travel to the rail ends

Overload limiter

Prevent for the overload

Wire rope guide

Align the wire rope neatly on the reel to prevent the wire rope from messing and overlapping

We have the short circuit protection, emergency switch, interlock protection, overload protection, loss of voltage protection, grounding protection and voice-activated alarm lights and other safety protection devices

FAQ

- Q1:What object to lift ? applications and working environment ?

- Q2:Lifting capacity:__ton?

- Q3:Lifting height (H):__ m ?

- Q4:Span (S):__m ?

- Q5:Travel bay distance:__m ? do you need us offer rails and runway beams ?

- Q6:Control mode: pendant control, remote control or cabin control ?

- Q7:Power source: AC 3Phase __V / __Hz ?