Recently we got the client visiting to our factory from Bangladesh. We had a very good meeting with client on company introduction, quality control, Technical discussion, logistic delivery and after-sales service.

Company introduction

Once client arrived our factory, we firstly introduced to client that our factory located in the China crane hometown-Chang’yuan and around 70% crane were produced in Chang’yuan. The crane business has been developed to one pillar industry with over 3000 manufacturers.

Kosta crane is a trusted professional & leading crane supplier. After more than 20 years of development, we currently has total assets of 3.8 billion yuan, a brand value of 3.9 billion yuan, more than 3,800 employees and an area of 1.65 million square meters.

Quality control

After our introduction, client ask one question to us: How you control the product quality? We answered him:

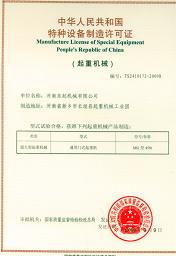

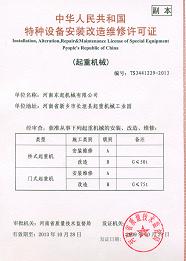

1, In China,if you want to produce the crane,you have to pass the government qualification review and get the production qualification.

2,Once we get the crane order from client, we will design the crane firstly based on client request. After the design, we will have the calculation report on the crane structural. Once the process has been approved. We will start the production.

We introduced our main girder production process, because We produce cranes in strict accordance with safety standards and regulations.

Mill test------shot blasting------primer painting-----Mark the layout on steel plate based on production drawing-------CNC cutting------double dragons automatic welding--------ultrasonic test on the welding------Manual welding for the rib inside of main girder---------Main girder assemble by submerged arc automatic welding------ultrasonic test on the welding----------Clear the welding slag---------check the main girder camber(When crane lift the material, there will be one deflection. And this is one testing point during the final commissioning)---------- Painting

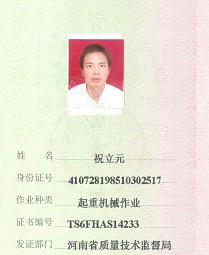

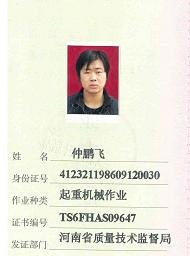

3, All of our workers such as the welder and electrician, they can start the work only obtain the skills certificate from the relevant department.

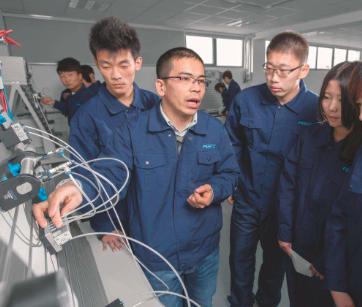

4, We will timely organize our workers to do the newly production technology study.

5, We can accept the client or third party factory inspections after the production. We welcome client come to inspect the crane to do the inspections before the balance payment and dispatch.

Technical discussion

We talked the trolley weight, gearbox installation position, working speed and motor brand etc. Finally after the direct face to face meeting, we solved the client all remaining technical concern issues.

Logistic delivery

1, Then we discussed with client about the delivery plan. We have to delivery the main girder by the 40GP container. If main girder above 11.8meters,it has been produced into 2 pieces. During the installations, the main girder will be connected again by our supplied high strength bolts and steel plate. Then weld again.

2, For the material, we will make the serial no. for each piece of crane part. Then we will supply client the details packing list with the each container loading details.

After-sales service

Finally, we talked the after-sales service with client.

1,We confirmed again to client that our warranty time is 18 months after the delivery or 12 months after the completely installations and commissioning.

During the warranty time, if crane damage comes from the crane itself, then we will afford the cost to maintain crane well; If damage comes from client unsafe control, we are responsibility to assistant client to maintain crane well.

2, We introduced to client again that we are the few manufacturers who can handle the crane productions from the crane parts (hook, wheel, pulley, drum, trolley and structural etc) to the completely set crane.

We have the stable and long-term parts supply system for the parts, so we can assure to supply client crane parts for a long time.

So after the fully efforts and discussions, we finally make the deal with client. Our business idea is “quality is the soul, we are making money for a the long term business, not the just once or twice times”.And this is the second order between us. We are expecting to work with client for the more coming chance.